Overview

The client is a Natural Gas operator in Appalachian that faced challenges managing potential landslides in their pipeline right-of-way. Initially relying on manual field inspections, the operator struggled with a reactive workflow that lacked a systematic approach to identify, rank, and monitor geohazards. The absence of a prioritization method led to 246 unprioritized geohazard slips, costing the company significant financial losses due to high repair expenses and frequent shutdowns.

Challenges Faced

The operator’s reactive approach to managing geohazards posed several challenges:

-

Lack of Prioritization: The absence of a systematic ranking method for hazards resulted in 246 unidentified and unprioritized slips.

-

High Repair Costs: Each slip incurred 2-3 times higher repair costs compared to mitigation, significantly impacting the company’s financial resources.

-

Frequent Shutdowns: Geohazard slips caused 3-5 shut-ins per year, costing the company a staggering $7 million per day during shutdowns.

Solution Implementation

Recognizing the need for a proactive and comprehensive solution, the operator enlisted the expertise of Teren and implemented their right-of-way integrity management program. Teren’s approach revolutionized the way geohazards were managed:

-

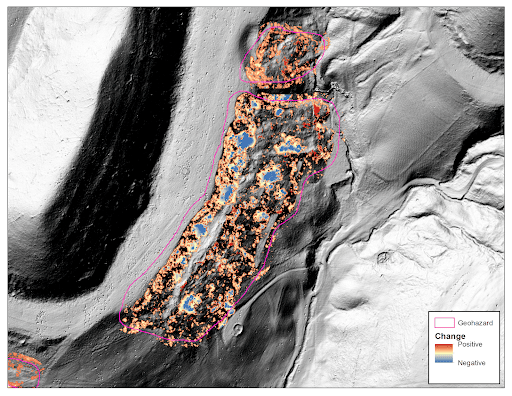

Resilience Technology: Utilizing a unique combination of ecosystem science expertise, high-performance geospatial computing, and remotely-sensed data, Teren identified potential geohazards that were invisible to the human eye.

-

Prioritization and Monitoring: The program ranked identified hazards, enabling the operator to prioritize mitigation efforts effectively. Furthermore, the system monitored changes in geohazards over time, offering insights crucial for proactive decision-making.

Results Achieved

The implementation of Teren’s program led to remarkable outcomes:

-

Significant Reduction in Unknown Slips: From 246 unidentified slips, the operator’s proactive approach reduced the number to a mere 12, signifying a drastic improvement in hazard identification and management.

-

Financial Savings: The proactive program slashed the repair budget by an impressive 90%, demonstrating the cost-effectiveness of mitigating hazards before they escalate.

-

Elimination of Shutdowns: By effectively managing geohazards, the operator achieved an unprecedented feat of zero landslide-induced shut-ins per year, eliminating the substantial financial losses incurred during shutdown periods.

Conclusion

Teren’s innovative approach empowered the Natural Gas operator to shift from a reactive to a proactive geohazard management program. By leveraging Teren’s resilience technology and scientifically-informed approach, the operator not only minimized financial burdens but also ensured operational continuity by preventing shutdowns. This case study highlights the invaluable role of proactive hazard management in the sustainability and efficiency of industrial operations, setting a precedent for enhanced safety and cost-effectiveness within the sector.

To learn more, watch our webinar detailing this unique story.